27.

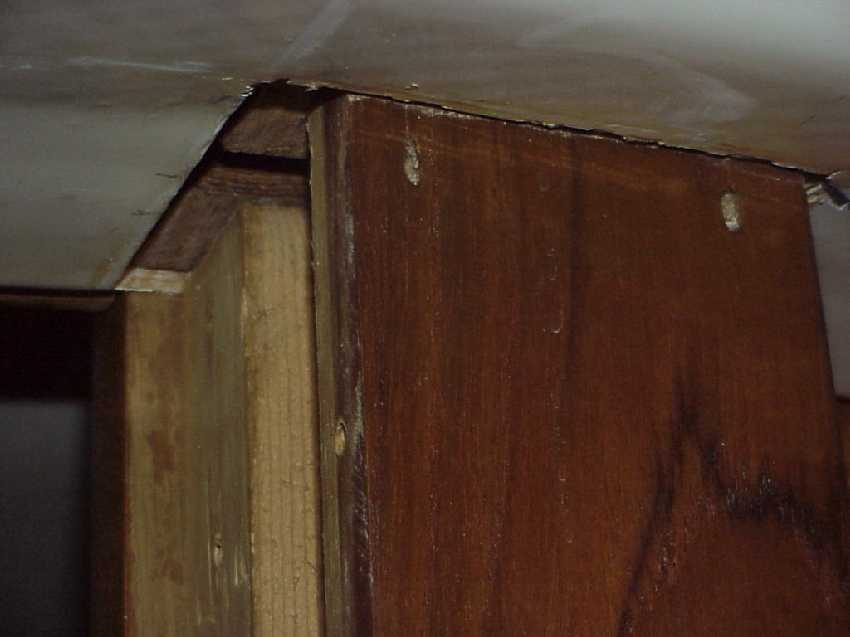

This is the port view of the compression post with the wire cover removed.

The reason these boats suffer damage to the athwart ship beam is because the factory screwed up on quality control. They

didn't insure that the space between the deck and contact patch for the compression post was completely full of suitable

wood. This is what I did to repair the factory work;

You will have to remove the mast. When you unscrew the molding at the top of the post, draw a line with a ink marker

around the top of the post on the glass of the beam. Then remove the post. You will have to jack the beam up. Cut the beam

with a dremel or similar cut-off tool, just INSIDE the ink line. The idea is to make sure the compression post will fit

INSIDE the cutout. That way NO weight from the mast will be on the beam. It becomes a decorative/wire chase beam only. You

will have to chisel out the old wood. Good riddance. Make sure the wood you remove is about the same size as the OD of the

compression post cutout. Then measure the void and find a suitable piece of wood that will fit snugly in your hole but loose enough so you can trial fit it and remove it for drilling. I used teak but I

think most wood will work. The factory used fur. You will then drill the required holes in the wood for cabling. Then

again lift the beam with a jack, enough to re-install the compression post. When you release the jack, make sure the

compression post fits inside the cutout you made with the dremel. It should fit so the glass of the beam drops around the

post about an 1/8 inch.

If you made your new insert so that you are SURE it is

tight against the deck and small enough so that it can be trial fit and drilled with a hole saw, the end result will be that

the load of the mast is now transferred via the insert, directly to the compression post and the beam does nothing but HOLD

THE COMPRESSION POST IN PLACE and that is MORE than the factory did. Any cosmetic damage remaining to the beam can be dealt

with as desired but don't spend a lot of money on glass work, just cover it with some kind of wood matching your decor. Not

counting mast removal, the cost of this work if you do it yourself, is next to nothing. I did it myself because everything I

was seeing on-line was too complex or expensive.

The top molding is ready to reinstall but I thought I would wait until we launch and do sea trials. That way the work will settle into place and the molding won't get crunched.

(11/14/3) Sea trials prove the repair to be perfect. The beam didn't sag any lower around the post and the mast shows no sign of the previous loose shrouds on the leeward side.